Digital Production Print Workflow Transformation with Revoria XMF PressReadyTM

Astragraphia Document Solution, 17 December 2024 – Principal of Astragraphia, FUJIFILM Business Innovation Asia Pacific launched Revoria XMF PressReadyTM, an innovative digital print workflow automation solution that brings production efficiency to a higher level.

With the increasing need for digital printing—from packaging to cards—and demands for faster processing times, MSME industry players face the challenge of remaining competitive in market share. Revoria XMF PressReadyTM is present as a solution to simplify the production process and significantly increase productivity on the Revoria Press series printing technology (*)

Main Advantages of Revoria XMF PressReadyTM

1. Smart Automation

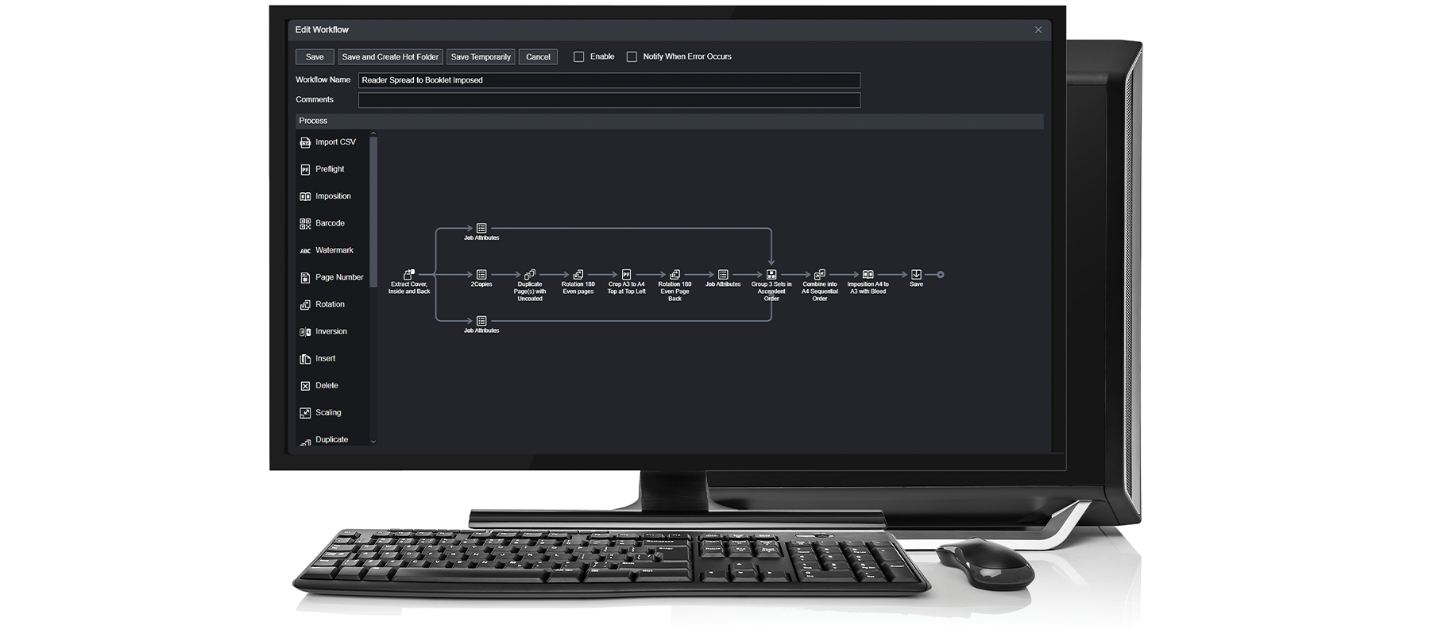

Revoria XMF PressReadyTM automates repetitive tasks through specific condition-based prepress settings. This allows operators to focus on other important aspects, minimizing manual intervention and speeding up workflow.

2. Production Flexibility

The software is designed to handle a wide variety of jobs from multiple sources, such as web-to-print, print information management systems (MIS), or PDF files, making it an ideal solution for small print runs with fast turnaround times.

3. Centralized Management

Revoria with automation capabilities and centralized management, Revoria XMF PressReadyTM is the answer for digital printing service providers to meet market needs more quickly and efficiently.

What is Revoria XMF PressReady?

Revoria With Revoria XMF PressReady, repetitive tasks such as pre-flighting, imposition, grouping, sorting, numbering and more can be automated. The software can also direct specific print jobs to the appropriate digital press based on predetermined conditions.

This automation significantly reduces human error and labor requirements to handle the large volume of small, variable print jobs that now make up the majority of print jobs. These solutions increase businesses' competitiveness by enabling them to handle more work in less time with fewer resources.

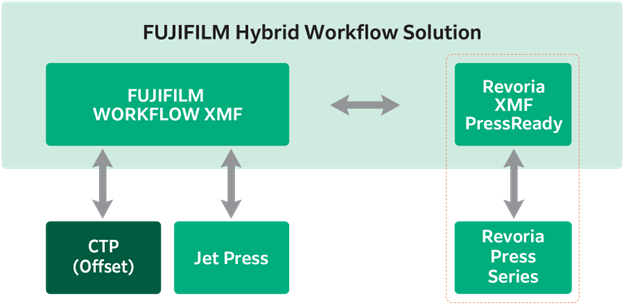

Revoria XMF PressReady Workflow Diagram

The following is an illustration of how Revoria XMF PressReady enables Print Service Providers to manage the Revoria Press series as part of a FUJIFILM hybrid workflow solution.

Main Advantages of Revoria XMF PressReady

1. Increase Productivity with Automated Print Workflow

• Automate repetitive manual tasks and decision-making processes using predefined condition-based branching logic for prepress jobs, job grouping, and file opening.

• Supports 24/7 printing even when the primary operator is not on site.

• This automation standardizes prepress workflows and increases ROI with consistent print results and minimal errors.

2. Better Monitoring with a Holistic System and Comprehensive Work Management

• Centralized platform enables job management and real-time monitoring of multiple printers on a single platform.

• Integrate workflows with Revoria Flow for a seamless process from start to finish.

3. Reduce the Potential for Human Error for More Cost-Effective Operations

• Increase print accuracy by reducing human involvement through touchless workflows.

• Reduces the need for manual repairs and additional resources due to human error.

Additional Features

Centralized Management of Jobs and Printers

• Monitor printer status (such as paper tray, media, and toner levels) in real-time to prevent unexpected downtime.

• View job list with print status, completion time, print queue and more.

• Easily modify the print quantity, media type, or specify a different output device.

Conditional Automation (Decision Making)

• Revoria XMF PressReadyTM enables user-defined rules and conditions to create dynamic, intelligent automation.

• This automation can make production decisions based on parameters such as size, quantity, orientation, media, number of pages, and others.

• Elimination of manual intervention saves time and reduces the risk of operator error.

Production Simplification

• This powerful and flexible work system optimizes digital production with automated processes, saving time and minimizing errors.

Integration into Existing Workflows

• Integrates easily with other systems such as the Print Management Information System and Web-to-Print System to ensure full connection between the ordering process and digital print production.

• Works seamlessly with FUJIFILM WORKFLOW XMF to manage offset and digital production in one integrated workflow.

• Full automation from order picking to finished product through configuration and integration with Revoria Flow.

Note: For complete printer model compatibility, please contact your local sales representative.

Source: FUJIFILM Business Innovation